Uncovering Biofuel Market Growth in PGM Catalysts

The European biofuel market is growing every year, driven by a rising demand for renewable and sustainable energy sources. In order to maximise the potential of this growing market, it is important to identify the most promising growth opportunities and explore the types of platinum group metal (PGM) catalysts used in the production of biofuels. This blog post will explore the state of the European biofuel market and provide an overview of the various PGM catalysts used in the industry.

The growth of the European biofuel market has been driven by a number of factors, including increasing public awareness of the need for sustainable energy sources, rising concerns over climate change, and government support in the form of subsidies, tax incentives, and mandates. According to a report by the European Renewable Energy Federation, the biofuel industry in Europe is expected to grow by over 5% per year between now and 2025, with new technologies and improved production techniques helping to increase efficiency and reduce costs.

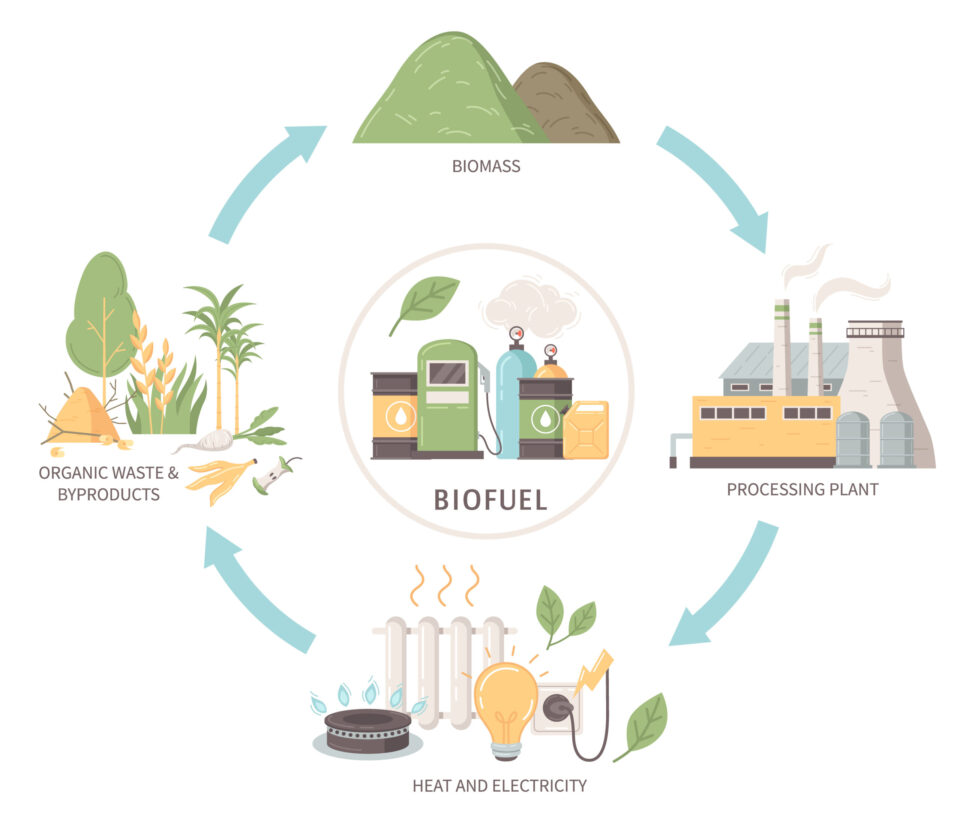

One of the key factors driving the growth of the biofuel market is the need to reduce greenhouse gas emissions. Biofuels are produced from renewable sources such as corn, sugarcane, and palm oil, and can be used as a substitute for fossil fuels in transportation, heating, and electricity generation. In addition to reducing greenhouse gas emissions, they can also improve energy security, reduce dependence on imported oil, and create jobs in rural areas.

The production of biofuels relies heavily on the use of catalysts, which are substances that increase the rate of a chemical reaction without being consumed in the process. PGM catalysts such as palladium, platinum, and ruthenium are commonly used in the production of biofuels due to their ability to increase the efficiency of reactions and reduce the amount of unwanted byproducts.

Palladium is one of the most commonly used PGMs catalysts in the biofuel industry. It is frequently used in the hydrogenation of vegetable oils to produce biodiesel, as well as in the production of bioethanol from corn and other starches. Platinum is also used in the production of bioethanol, as well as in the production of bio-oil from algae and other biomass sources. Ruthenium is less commonly used, but has been shown to be effective in the production of bio-oil from sewage sludge and other waste materials.

Palladium is one of the most commonly used PGMs catalysts in the biofuel industry. It is frequently used in the hydrogenation of vegetable oils to produce biodiesel, as well as in the production of bioethanol from corn and other starches. Platinum is also used in the production of bioethanol, as well as in the production of bio-oil from algae and other biomass sources. Ruthenium is less commonly used, but has been shown to be effective in the production of bio-oil from sewage sludge and other waste materials.

Sustainable aviation fuel (SAF) is also an alternative renewable biofuel used to reduce air transport’s carbon footprint. Platinum or palladium catalysts enhance fuel quality by removing impurities, reducing sulphur content, and improving energy density and combustion efficiency. Their use ensures SAF meets aviation standards, lowers greenhouse gas emissions, and promotes a more sustainable aviation industry.

Conclusion

In conclusion, the European biofuel market is a rapidly growing industry with significant potential for further growth in the coming years. As demand for renewable energy sources continues to rise, the importance of identifying the most promising growth opportunities and exploring the types of PGM catalysts used in the production of biofuels cannot be overstated. By investing in research and development and improving production techniques, it is possible to maximise the potential of this important industry and help to create a more sustainable future for all.

Mastermelt with locations in UK, Germany, USA and Singapore have the experience and expertise to process and implement the precious metal catalysts recovery of these precious metals from Biofuels. Supporting customers on their journey to a more sustainable future.